Pre-Drilling Hardwood Terrace Planks

Pre-Drilling Hardwood Screw Holes

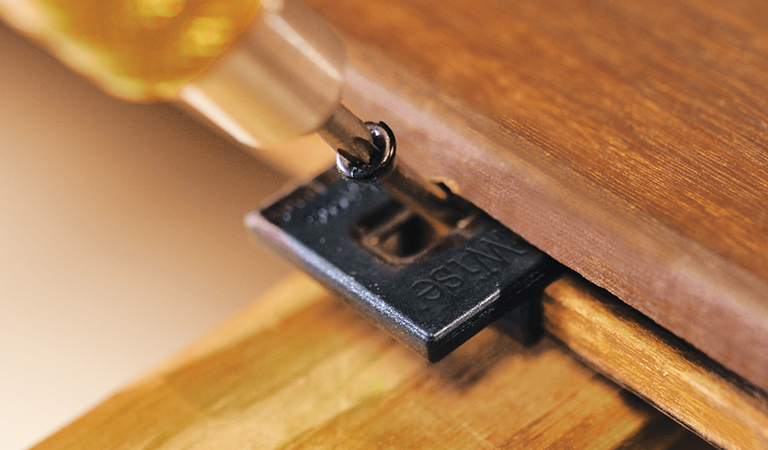

Both Self-Drilling and Trim-Head hardwood screws work very well for any installation. However, when exotic hardwood timber is used, we consistently advise pre-drilling pilot holes for screws. Pilot holes are drilled to ensure your costly exotic hardwood planks will not crack when securing screws into terrace fixings or hardwood cladding fixings. Thus, fewer plank overage is needed per job site. This means overall costs are reduced and profits are held high.

Pre-Drill, Countersink & Drive Screws

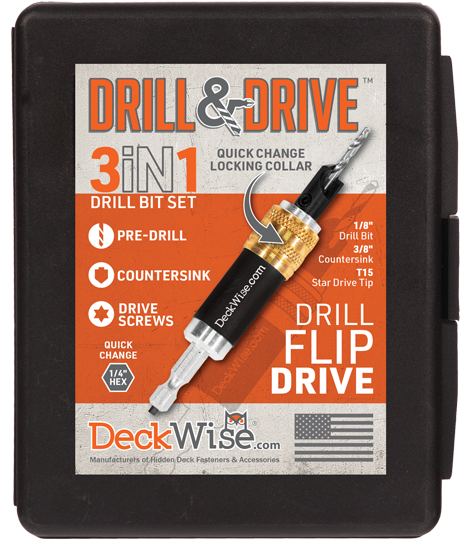

Use the DeckWise® 3-In-1 Reversible Drill Bit Set to make your installation 30% faster... Read More

Eliminate Screw Stress

Pre-drilling screw holes will remove the stress (torsion) along the screw shaft when screwing. This in turn will prevent the possibility of a plank cracking or splitting. Pre-drilling will also permit the screw to be backed out easily if needed.

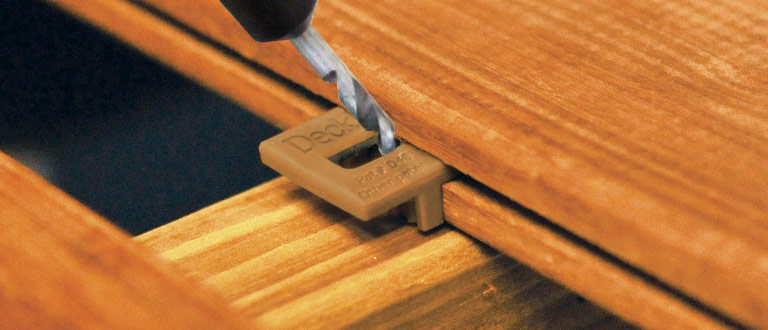

Furthermore, exotic hardwoods have extremely dense timber fibers. That means excessive heat from friction is generated during screwing. The heat generated by friction can often reduce the ability of the screw to properly penetrate into the terrace plank. This can increase installation time and raise labor costs. Pre-drilling pilot holes removes the friction-generated resistance and allows the screw threads to bite into the timber properly for maximum grip.

Pre-drilling also removes adequate timber fibers from the insertion hole. Screw threads will then be able to bite into the timber properly. Screws will not back out due to pressure or force from excess timber fibers during expansion of the plank. This is extremely important to ensure a profitable hardwood installment and to not waste man-hours due to questionable installation methods.

Small Screw Heads

Trim-Head and Heat-Treated Self-Drilling screw styles are perfect for EXTREME® invisible terrace fixings and invisible cladding fixings. Both trim-head and heat-treated screws arrive with small heads to ensure it is as discrete as possible. Each has their own anti-corrosion feature and will not damage or stain timber planks. The advantage of these screw heads is that they will not protrude above the surface of the fixing and the stainless steel metal will last a lifetime.

Likewise, the small head of these screws tuck neatly into countersunk holes drilled for hardwood plugs. There is no need to worry if screws will not fit into the countersunk hole. This also makes installing screws from the top side fast and very effective.

Pre-Drilling Reduces Timber Splitting & Cracking

Most hardwood timber has a very low moisture content – kiln dried around 15% and Air dried about 20-25%. This means an expensive Ipe terrace plank could easily crack or split even though it has a hardness Janka Rating of 3684. Less moisture means less acceptance to pressure and force during installations. Pre-drilling ensures against planks cracking and splitting.

Easily Unscrew Terrace Screws

When a timber screw needs to be backed out (unscrewed) there is a very good possibility it could break if the screw hole was not pre-drilled. Stress that is placed on the timber screw during installation can be doubled as the screw treads reverse themselves, including generating heat from friction once again. When terrace or cladding fixing screw holes are pre-drilled it assures easy removal and guarantees timber planks will not crack or split.

Save Money. Save Time.

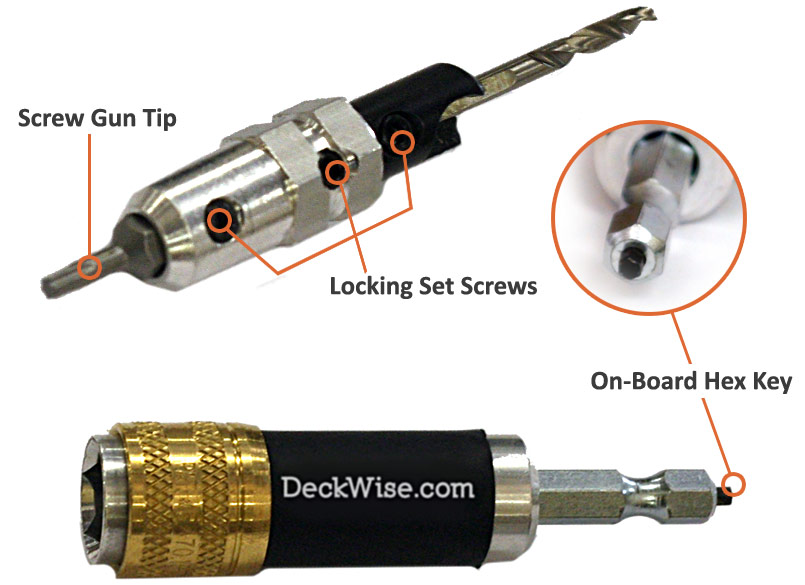

Some builders believe pre-drilling will add excess labor to the job and prefer to skip pre-drilling. In spite of this, when installers use the DeckWise® Drill & Drive™ installations are actually quite quick due to the rapid change locking collar on the removable chuck. There is no need for multiple cordless screw drivers and multiple tips. When considering the added time needed to remove a broken screw verses pre-drilling holes, our drill bit set is always faster and, much, much, more efficient.

*Replacement bits and tips sold separately

*Replacement bits and tips sold separately

Pre-Drill. Countersink. Drive. 3-In-1 Reversible Drill Bit Set

Whatever installation job you face, the Drill & Drive™ drill bit set has every bit you need in one convenient carrying case. Despite whether the job demands quick, clean countersunk holes for top side face screwing terrace planks or fastening hardwood cladding planks, this tool kit is perfect for professionals and DIY homeowners.

The Drill & Drive™ drill bit set is what makes our installation method extremely efficient. There are no other building tools that rapidly flip back and forth between drill bits and screw tips the way this tool does.

Just as importantly, we understand builders' and contractors' need to get to the next job quickly to maintain high profit margins. Avoid losing labor costs, make the change to improved production!

![]()