DeckWise® Extreme® Invisible Terrace Fixing

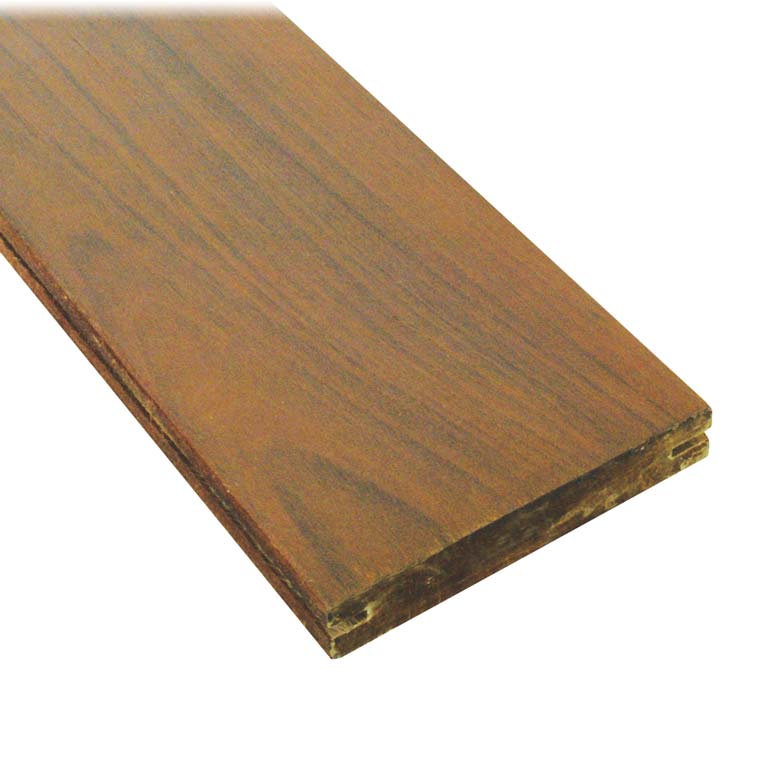

Invisible Terrace Fixing For Hardwoods (2,4mm)

For Air-Dried Timber, Thermal Wood & Composite Terrace Materials

Product Features:

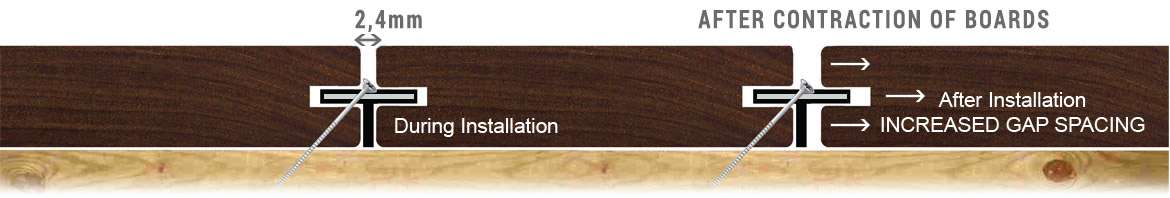

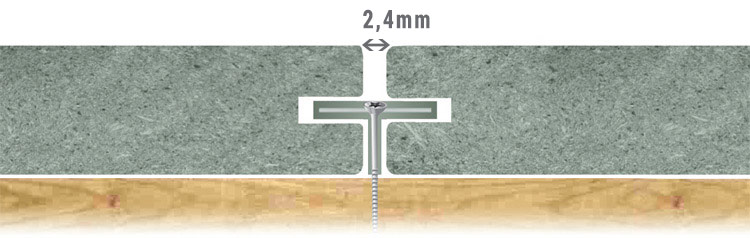

- Spacer wedge leg precisely spaces planks 2,4mm apart

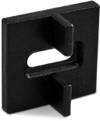

- Injection molded with high hardened polypropylene resin

- Embedded stainless steel insert for strength

- Black oxide coated insert protects against corrosion

- Screws installed at a 45° angle for maximum holding strength

- Suitable for air dried hardwoods, composite, or thermo wood materials

- Permits air dried imported timber expansion on plank width

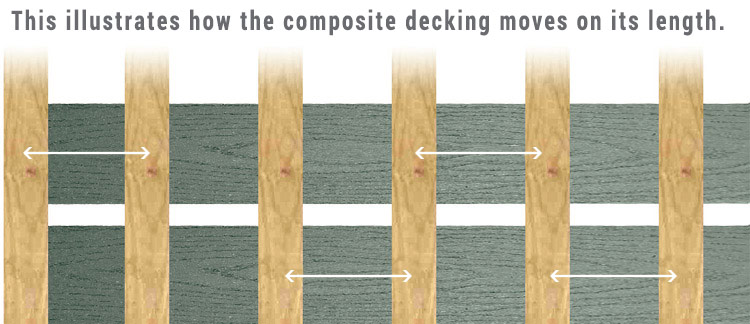

- Permits PVC and composite plank movement on plank length

- Unique design ensures more contact area inside plank slot groove

- Polypropylene shell resistant to damaging UV sun rays

- 3 clip color options to match terrace material

- Limited Warranty

- Premium American Made & U.S. patented

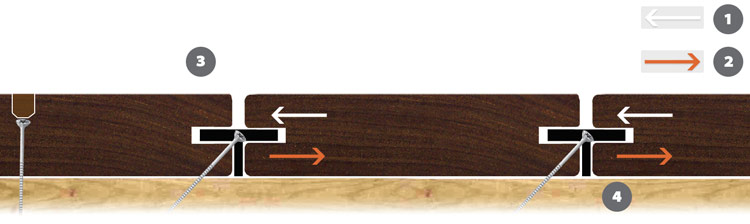

Terrace Planks Remain in Place

Perfectly Spaced 2,4mm Gap Positioning

1. Path of plank expansion

2. Plank contraction direction

3. Top-side of the terrace planks

4. Screw install side of planks

What makes our Extreme® invisible terrace fixing and slot groove method distinctive is that, just one side of the timber plank is secured to the joist below. This enables the opposite side of plank to move naturally on its width when contraction and expansion occur. This unique installation method guarantees secure and even gap spacing along planks over time.

Extreme® Hardness Allows Plank Width To Expand

Polypropylene Resin Guarantees Long-Term Performance

1. Tempered stainless steel strengthening insert

- Ensures accurate screw positioning and avoids over-driving

- Painted with black oxide for extended anti corrosion

- Hardened stainless steel reinforcing insert embedded inside fixing

2. Polypropylene Plastic Resin Biscuit Shape

- Biscuit design ensures maximum contact with timber channel

- Injection molded polypropylene resin for toughness

- Spacer wedge leg retains shape following timber expansion

Developed for imported timber terraces, the coloration of the plastic polypropylene resin additionally disguises and conceals our invisible fixings among the plank gap spaces. Also ideal for thermally treated terrace timber planks!

Our powerful stainless steel insert securely holds planks to joist sleepers, reducing any chance screws may pull through the fixing as hardwood timber naturally moves. The Extreme® fixing offers up to 3X additional hold-down resistance than other slot groove fixings without a stainless steel insert.

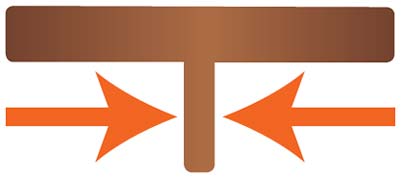

Included Spacer Wedge Leg

Guaranteed 2,4mm Gap Space Between Timber Planks

1. Spacer wedge leg on the Extreme® clip will not react with timber oils negatively.

2. The 2,4mm spacer wedge leg ensures consistent intervals between planks.

3. Timber contraction and expansion absorption capacity with memory.

4. Absorbs the expansion of timber and will not damage the edge of the plank.

Guaranteed Even Plank Spacing

Polypropylene Plastic of High-Quality

Wedge legs absorb compression pressure and hold shape

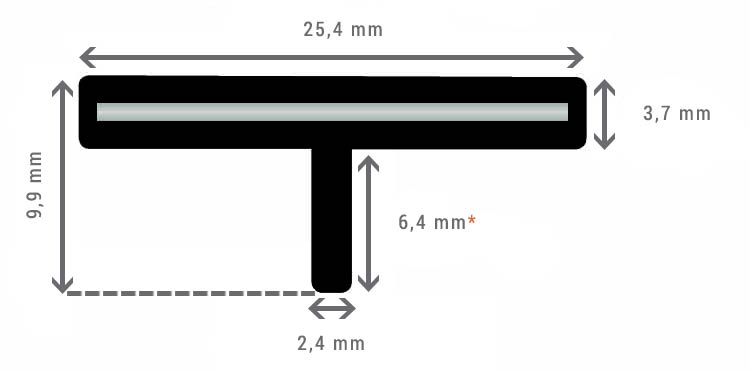

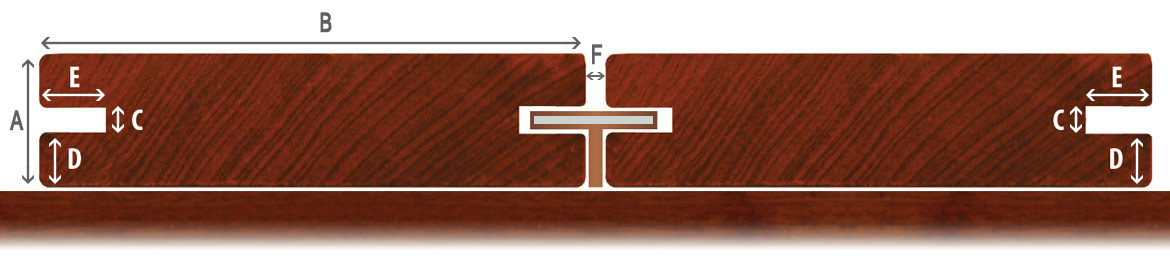

Fixing Dimensions

Invisible Clip Construction

| Material | Stainless Steel Insert | Available Color |

|---|---|---|

| Polypropylene | 22,4 x 22,4 x ,9mm |  |

Timber Compatibility

| Air-Dried Timber | Kiln-Dried Timber | Composite Material |

|---|---|---|

Resources for Architects & Builders

CSI Divisions & SpecsEnables Contraction on the Width of Air-Dried Timber

Our method of installation uses screws secured at a 45 degree angle through the clip into the timber planks. This firmly attaches the plank to the sleeper joists and also allows one side of the timber plank to remain entirely free to move with natural contraction and expansion. Pre-drilling pilot holes is recommended to ensure hardwood planks do not split or crack.

Screwing Planks into Terrace Joists

Invisible Terrace fixings are screwed through the timber plank slot groove down into the joist at a 45° angle.

The capability to use anchoring screws at a 45 degree angle down through the hardwood plank highly increases hold down force. Research has proven that, anchoring screws have additional holding power when run at an angle. This allows screw threads additional grip across lateral timber fibers.

- Pledges a powerful solid terrace, totally free of screw heads

- Small screw head fits neatly inside the stainless steel insert

- Easily install Extreme® fixings from the top-side down, not from below

- 45° angled screw holds tightly as timber naturally contracts and expands

- 305 Grade stainless steel will not corrode and will last a lifetime

- Self-drilling screws make installments efficient and quick

Allows Contraction & Expansion on the Length of PVC/Composite Materials

Driving a stainless steel screw straight down at a 90 degree angle through our fixing works best with composite and PVC materials. Generally there is simply no need to install screws through the composite plank itself. Composite material expands and contracts on its length, not its' width. Plank gaps still remain exact and fixings are invisible within the plank gaps.

DeckWise® Extreme® Clip Installation Guidelines

Plank Compatibility

| Plank Thickness | Plank Width |

|---|---|

| *A = Measurement Of Plank Thickness | **B = Measurement Of Plank Width |

Slot Groove Dimensions

| Thickness of Cut | Cutting Height | Cutting Depth |

|---|---|---|

| C = 4mm | ***D = (A-4mm)/2 | E = 13mm |

Plank Spacing

| During Installation |

|---|

| ****F = 2,4mm |

* If utilizing 38,1mm or thicker material, longer screw options may be required than what is generally included with the concealed fixing kit.

** For terraces 20,32cm or wider, the (A) dimension must be at least 38,1mm. Utilizing a wide plank such as this for exterior terraces will almost certainly generate cupping issues despite of how the material is secured if thicker material is not used.

*** This formula will produce a symmetrical installation profile that enables you to reverse and/or rotate the plank to be able to place the ideal side up.

**** Fixing instantaneously achieves proper gap spacing when planks are pushed close together in the course of installation.

Symmetrical & Reversible Timber Planks

Choose the Best Side of Your Timber Plank to Install

- Symmetrical Edge Grooves: Terrace planks have symmetrical side slot grooves which are centered in the sides of each plank.

- Smooth Plank Surfaces: Because our system uses a symmetrical groove on each side, either side of a plank can be installed depending on best beauty.

Whatever type of hardwood or thermally modified wood you install, timber planks are not always perfect on both sides. Most terrace fixing methods have a side slot mount profile which does certainly not allow planks to be turned for the ideal smooth surface. This is not true about our Extreme® invisible fixing profile.

If an installer comes across a defect on a section of a timber plank, merely flip the plank and install the best side face up. Since our method employs use of either side of the plank, set up time is enhanced and earnings are not lost on planks which cannot be installed.

Inquire with your timber yard to pre-groove your terrace planks or utilize a biscuit slot cutter on the work site.

Plank Replacement Steps

Review these instructions to replace damaged timber planks

DeckWise® Extreme® concealed terrace fixings have the extra advantage of effortless and simple plank replacing. Generally there is no need to dismantle the terrace just to take out a damaged timber plank. Just follow this hyper-link to see the actions required in our Plank Replacement Guide.

Plank Replacement GuideAvailable Terrace Clip Kit Options

DeckWise® Invisible Terrace Clip kits (185 count) can also be combined with substitute combinations of our trim-head screws or our heat-treated screws. Concealed Fixing Kits can also include assorted terrace clip colors as well as various ranges of spacer wedges for specific installments.

Complete Kit

- (185) DeckWise® Extreme® Invisible Clips

- (200) 4 x 50mm Stainless Steel T15 - Star Drive Black Screws

- (12) 9,5mm Tapered Ipe Plugs

- (1) 3,2mm High Speed Drill Bit

- (1) T15 Star Driver Tips

- (1) Instruction Sheet

555 PRO Bucket

- (555) DeckWise® Extreme® Invisible Clips

- (600) 4 x 50mm Stainless Steel T15 - Star Drive Black Screws

- (3) 3,2mm High Speed Drill Bit

- (3) T15 Star Driver Tips

- (1) Instruction Sheet

Extreme®

Stainless Steel Screws

T15 Star Drive Tip

3,2mm Drill Bit

9,5mm Plugs

DeckWise® Invisible Terrace Clip Limited Warranty

To make a DeckWise® product claim, warranty registration form must be completed here:

www.deckwise.eu/en/warranty